The Vendor Return Process in SAP is an essential part of supply chain management. It allows organizations to efficiently manage the return of goods to vendors, ensuring accurate inventory levels, financial tracking, and streamlined communication. Let’s outline the key steps involved and some important considerations:

Key Steps:

- Create a Return Purchase Order: The process initiates with creating a return purchase order in SAP. This document specifies the materials to be returned, the quantity, the reason for return, and any relevant vendor information.

- Goods Receipt for Return Delivery: Once the return purchase order is created, the goods are physically returned to the vendor. In SAP, a goods receipt is posted against the return purchase order to record the return delivery.

- Credit Memo from Vendor: Upon receiving the returned goods, the vendor issues a credit memo. This document serves as a confirmation of the return and details the amount to be credited to the organization.

- Verify Credit Memo and Post in SAP: The credit memo received from the vendor is verified against the return purchase order and goods receipt. Once verified, the credit memo is posted in SAP, leading to an update in the financial accounts and inventory records.

Important Considerations:

- Reason for Return: It is crucial to accurately document the reason for the return. This information helps in analyzing return trends, identifying potential quality issues, and improving vendor relationships.

- Material Inspection: Depending on the nature of the returned goods, an inspection may be required to assess their condition and determine appropriate action.

- Return Authorization: In some cases, a return authorization from the vendor may be necessary before initiating the return process.

- Transportation: The logistics of returning the goods, including transportation arrangements and associated costs, should be considered and managed effectively.

- Financial Impact: The financial implications of the return, including any potential impact on accounts payable and inventory valuation, should be carefully tracked.

Benefits of a Well-Managed Vendor Return Process:

- Improved Inventory Accuracy: Efficient handling of returns ensures that inventory records are updated promptly, leading to improved accuracy and informed decision-making.

- Enhanced Vendor Relationships: A streamlined return process fosters positive vendor relationships, contributing to better communication and collaboration.

- Cost Savings: Effective management of returns can help identify cost-saving opportunities, such as reducing unnecessary returns or negotiating better terms with vendors.

- Compliance: A well-documented return process supports compliance with regulatory requirements and internal controls.

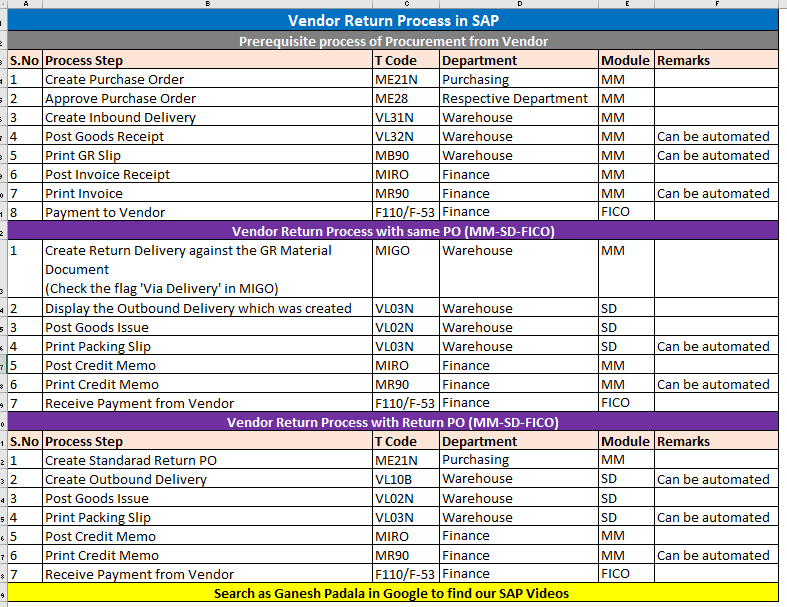

Two types of Vendor Return processes are used in SAP. I have provided the steps along with the differences below.

Steps:

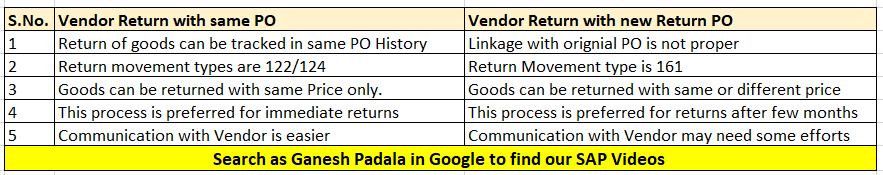

Differences between Vendor Return with same PO and Different return PO:

If you have any more questions, you can ask in comments. Keep learning and keep sharing. Thanks.

Best Regards,

Ganesh Padala

What will be the impact of credit memo on material valuation i.e. materials having MAP?

LikeLike