What is an SAP Physical Inventory Document?

In SAP’s Inventory Management module, a Physical Inventory Document is a critical record that captures the results of a physical inventory count. It serves as a bridge between the actual, physical quantities of materials in your warehouse or storage locations and the quantities recorded in your SAP system.

Key Functions and Significance

- Discrepancy Identification: The core purpose of the Physical Inventory Document is to identify discrepancies between the book inventory (what SAP thinks you have) and the actual physical inventory count. These discrepancies can arise from various factors like theft, damage, incorrect postings, or simple human error.

- Inventory Adjustment: Once discrepancies are identified, the Physical Inventory Document facilitates the necessary adjustments to the inventory records in SAP. This ensures that your system accurately reflects the real-world stock levels.

- Audit Trail: The document provides a detailed audit trail of the physical inventory process, documenting who counted which materials, when they were counted, and any discrepancies found. This is vital for compliance and internal control purposes.

- Decision Support: By analyzing the discrepancies highlighted in the Physical Inventory Document, businesses can gain insights into potential problem areas in their inventory management processes. This information can be used to improve accuracy and efficiency.

Typical Process Flow

- Physical Inventory Count: The actual counting of materials in your storage locations.

- Document Creation: In SAP, a Physical Inventory Document is created, referencing the relevant storage locations and materials.

- Count Entry: The counted quantities are entered into the document.

- Posting: The document is posted, triggering the necessary inventory adjustments in SAP.

Key Transaction Codes

- MI01/MI02/MI03: Create/Change/Display Physical Inventory Document

- MI04/MI05/MI06: Enter/Change/Display Count results

- MI20: Check discrepancy results

- MI07: Post Differences

Points to Note

- Physical Inventory Documents are legally required in many countries.

- They are an essential part of any well-run inventory management system.

- SAP offers flexibility in how you configure and use Physical Inventory Documents to suit your specific business needs.

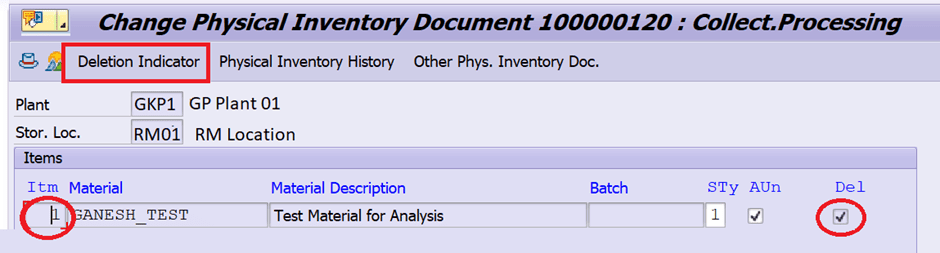

Physical Inventory Document can be deleted with MI02 Transaction Menu —> Physical Inventory Document —> Additional Functions —> Delete.

Few key points to note about the PID deletion. Both deletions are possible with transaction code MI02.

Header Level deletion:

Item Level deletion:

You can find the below table where I provided the behaviors and table details related to both deletions as per the different stages related to Physical Inventory Document.

| Stage of PID Document | Header level deletion | Item level deletion |

| Before the stock count | 1. PID can be deleted at header level before the stock count. 2. It will delete the number completely from the data base. | 1. Deletion flag can be kept for required items in a Physical Inventory document. 2. Document will be available in system which can be displayed with MI03 transaction. 3. The details can be found in table ISEG under field XLOEK. If all the items are flagged with deletion indicator means, system will consider as header level and remove the document from the data base. |

| After stock count and before posting the differences | ||

| After posting the differences | 1. PID can be deleted at header level after the stock differences are posted with MI07. 2. It will keep the deletion flag to the Physical Inventory Document in the data base table IKPF under the field LSTAT if the PID is deleted at header level. | 1. Item level deletion flag is not possible for the document which is already posted for the differences. |

Thanks and Best Regards,

Ganesh Padala

Watch to Learn and Share to Help.